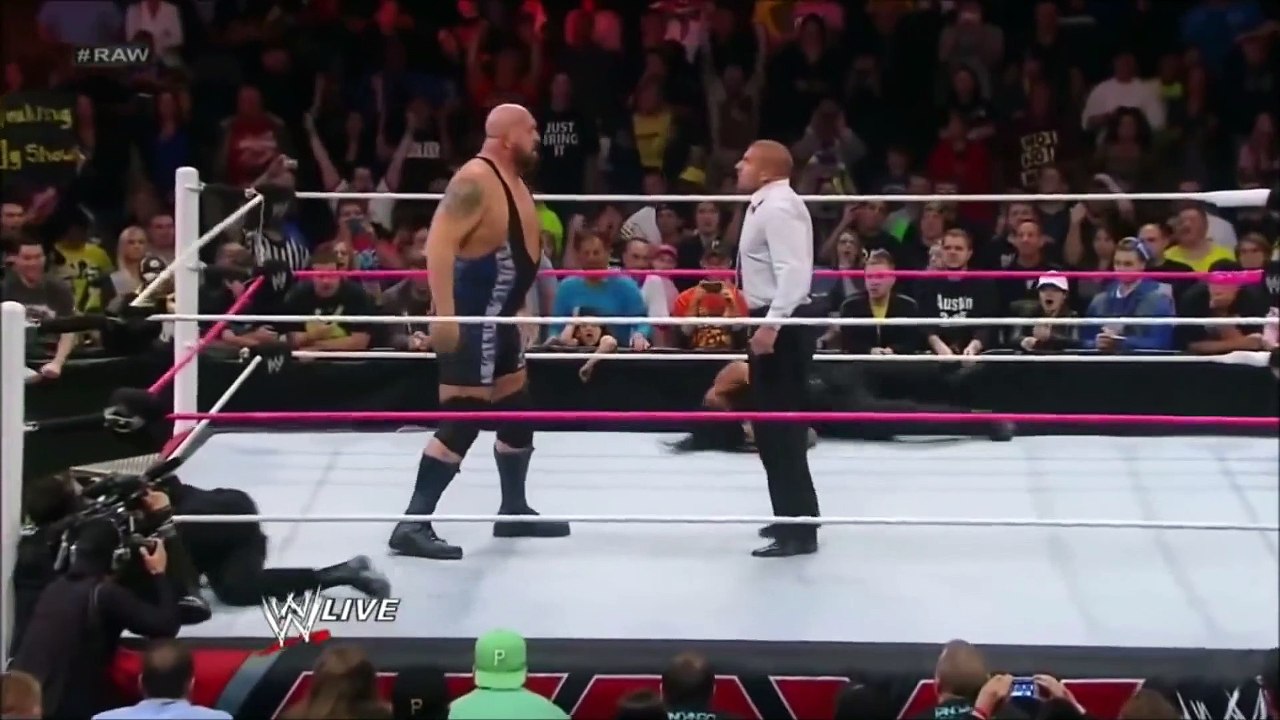

WWE TOP 20 KNOCKOUT PUNCHES OF ALL TIME

A knockout (abbreviated to KO or K.O.) is a fight-ending, winning criterion in several full-contact combat sports, such as boxing, kickboxing, muay thai, mixed martial arts, karate, some forms of taekwondo, and other sports involving striking, as well as fighting-based video games. A full knockout is considered any legal strike or combination thereof that renders an opponent unable to continue fighting.

There are several sizing systems for these punches. The two most common are those sized for standard electrical knockout sizes and those that are for true dimensional holes. A 3/4 inch conduit size punch actually punches a hole that is approximately 1.1 inches diameter for 3/4 nominal size conduit. A dimensional size punch makes a hole very close to the indicated size. Punch sets are available on both imperial and metric sizes.

Chassis punches are available in a number of shapes, round being the most common. Other shapes include square, hexagonal, and special shapes for thing such as holes with key tabs and D-sub connectors[7] Special shapes often use bolts that are square or keyed and a separate nut on the punch end to ensure alignment of the punch and die.

References

Benchmark Media UK, Producing Sheet Metal Components and Assemblies, Benchmark Media Limited, p. 50.

Fournier, Sue (1990), Metal fabricator’s handbook, HPBooks, p. 16, ISBN 978-0-89586-870-1.

Miller, Rex (2000), Electrician’s Pocket Manual, McGraw-Hill Professional, pp. 43–44, ISBN 978-0-07-136026-5.

Tuck, David (2003), Electrician’s Instant Answers, McGraw-Hill Professional, p. 240, ISBN 978-0-07-140203-3.

Fletcher, Gregory W. (2003), Residential Construction Academy House Wiring, Cengage Learning, p. 70, ISBN 978-1-4018-1371-0.

“Knockout punch”, Popular Mechanics, 94 (3): 139, September 1950, ISSN 0032-4558.

Greenlee panel punches, archived from the original on 2014-05-08A knockout punch, also known as a chassis punch, panel punch, Greenlee punch, or a Q-max,[1] is a hand tool used to punch a hole through sheet metal. It is a very simple tool that consists of a punch, die, and screw. There are three different drive systems: manual, ratchet, and hydraulic.[2]

Operation

First a pilot hole is drilled slightly larger than the screw of the knockout punch. Then the die is placed on the screw and the screw is inserted into the pilot hole. The screw is then threaded into the punch and the screw tightened until the punch is drawn completely through the sheet metal.[2]

The manual system uses a screw that has a standard hex head or square head and is driven using an allen key or wrench. A manual knockout punch can handle holes from 0.5 to 1.25 in (13 to 32 mm). The ratchet system has a custom ratcheting wrench that uses a ball screw to make the process faster and easier. This type of system has a mechanical advantage of approximately 220:1 and can punch holes up to 3 in (76 mm) in diameter in 10 gauge mild steel.[3] A hydraulic system is much bulkier and heavier than the othe